Explosion Proof Booms and Scissors Lifts

Explosion Proof Booms and Scissors Lifts

Aerial work platforms have strict, well defined safety requirements including stability and stress analysis and control system functional safety.

Bailey Develops Next Generation Explosion-Proof Aerial Work Platforms

As developers of the original EX Series Explosion-Proof lifts back in 2002, many things have changed including ANSI Standards and better Intrinsically Safe Technology. The original EX technology was developed under Man Lift Engineering, Bailey’s first company which was sold in 2010. Every major aircraft manufacturer in North America utilized these lifts as well as many ship and general industrial painting operations.

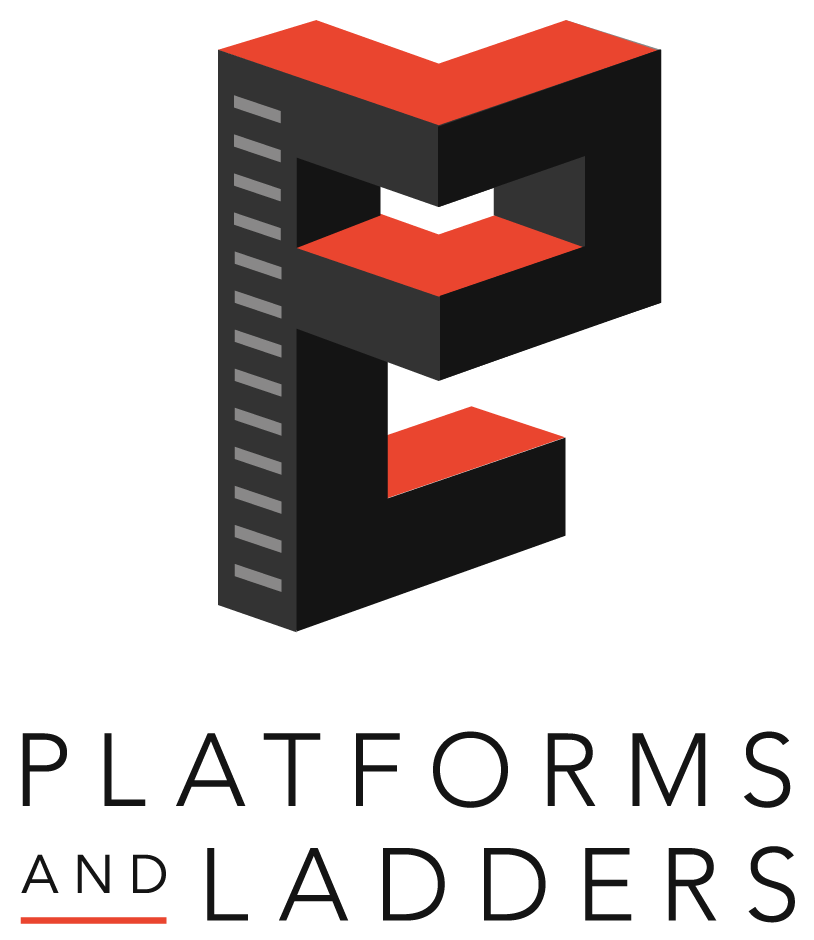

While the original technology served its purpose, advances in EX technology have made earlier systems obsolete. Complicated hydraulic systems resulted in extensive use of hydraulic hoses which caused many leak points and a maintenance nightmare. Better motor switching technology results in longer life and reduced maintenance.

The original ANSI standard in 2002 was A92.5 and A92.6. Currently the ANSI standard is A92.20. The most significant change is platform load sensing. The ability to sense the load in the platform and stop functions for safety. Our new systems incorporate this load sensing technology compliant with EX explosion-proof standards.

Not just experts on EX technology, Bailey has a long history of building custom Aerial Work Platforms for a variety of industries. The backbone of our expertise is extensive Standards involvement including past committee members on the following:

ANSI A92.5 Boom Supported Elevating Work Platform

ANSI A92.6 Self-Propelled Aerial Work Platforms

NFPA 505 Fire Safety Standards (Explosion-proof) for Industrial Trucks

UL 583 Safety Standards - Battery Powered Industrial Trucks

UL 588 Safety Standards - Internal Combusion Engine Industrial Trucks

When building or modifying Aerial Work Platforms there are strict, well defined safety requirements that can not be overlooked including stability analysis, stress analysis and control system functional safety. Bailey is expert on all of these. Others in the industry appear to have experience in EX technology but not Aerial Work Platform experts. Do their modifications affect machine stability? Do their control system modifications meet the ANSI requirements? Raising personnel 80 feet in the air has significantly more Safety Risk as compared to modification of a forklift. The Safety Risk is great. Another competitor was recently sold to a fabrication house thinking that building off a set of drawings is good enough. Not having extensive EX experience is a Safety Risk.

The Engineers at Bailey have been involved in the development of the following products:

Clean Room lifts at Cape Canaveral preparing satellites for launch up to 135’ sold to United Launch Alliance.

Aircraft painting EX lifts sold to Boeing, Lockheed Martin, Northrop Grumman, Bombardier and Gulfstream.

Specialized lifts building aircraft for Boeing and Spirit Aerospace.

Rocket Launch Platform, Up Aerospace – The first commercial launch company located at Spaceport America.

Call for more information on explosion proof lifts.